Acoustic boards help lessen undesirable reflected sound in any room...

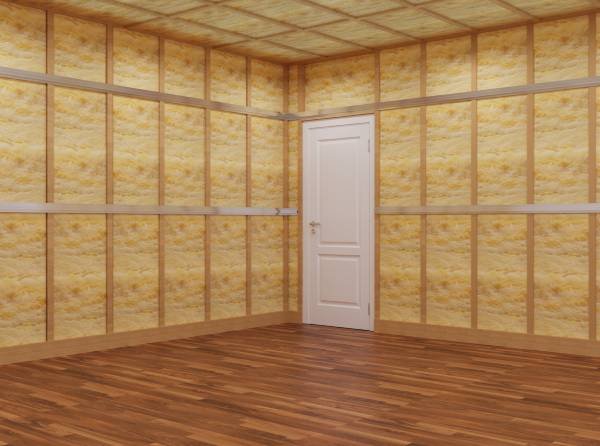

Fibreglass insulation is a popular choice. One of its key characteristics is its value. Fibreglass insulation is less expensive to instal than many other types of insulating materials, and it is often the most cost-effective option for equal R-Value performance when compared to cellulose or spray foam insulation systems (i.e., thermal resistance). Because of the method fibreglass is made, which includes weaving small strands of glass into an insulation layer, it can limit heat transfer. It is vital to wear the right safety equipment when installing fibreglass, as glass powder and tiny shards of glass are formed, creating a danger of harm to the eyes.

Blankets come on continuous rolls, whereas bats are precut. The material’s efficacy is reduced when it is compressed. Cutting it to make room for electrical boxes and other obstructions allows air to flow freely through the cavity of the wall. For improved effectiveness in minimising heat bridging, put batts in two layers across an unfinished attic floor, perpendicular to each other. Blankets can be used to cover joists, studs, and the space between them. Batts can be difficult and unpleasant to hang between joists under floors; straps, or staple cloth or wire mesh over joists, can help.

Fiberglass Ceiling Tiles have a non-woven fibreglass or glass wool mesh core that is totally enclosed with either a square or a tegular edge. Silica sand is used to make Fiberglass or glass wool, which is a reusable and environmentally favourable green material. This is also one of the greatest insulation materials on the market, both in terms of thermal and acoustic insulation. Even when in direct and continuous contact with flames, it is a non-combustible material. It does not produce toxic gases or smoke, which are two of the most dangerous health and life threats in the case of a fire.

Cleaning up the waste after a home renovation job can be stressful. If you’re stuck with old ceiling tile, make sure you properly dispose of it or face a fine from your municipality. Any ceiling tile that does not contain asbestos can be readily disposed of or recycled. The procedure is simple and will take some physical labour to move the tile as well as some research to choose your best disposal choice.

Glass wool, commonly known as fibreglass, is created from a blend of natural and recycled glass (recycled bottles, vehicle windscreens, and window panes) that is melted at 1,450 degrees Celsius and spun swiftly into threads. After that, the fibres are bonded together and utilised as insulation. Because air is a poor conductor of heat, the glass fibres form pockets of air that act as barriers to limit heat loss. Glass wool is available in batts and rolls, as well as insulation boards.

Stone Wool is manufactured from volcanic rock (dolomite, diabase, and basalt), which is not recyclable but abundant. Slag wool is manufactured from a blast furnace’s recycled waste product. Despite the fact that the two are sometimes referred to as Rockwool, Stonewool produces a higher quality and performance product than Slag wool. These raw materials are processed in the same manner that glass is prepared: they are melted at high temperatures (about 1,500°C) and then spun into fibres. After that, the wool is packaged into batts, rolls, or slabs. The advantages of rockwool insulation over glasswool insulation have been hotly debated.

The eyes, skin, and respiratory system will be irritated by fibreglass. Irritation of the eyes, skin, nose, and throat, as well as dyspnea (breathing problems), sore throat, hoarseness, and cough, are all possible symptoms. When suggested work methods are followed to reduce transitory mechanical irritation, scientific evidence shows that fibreglass is safe to manufacture, instal, and use. Unfortunately, these work procedures are not often followed, and fibreglass is frequently exposed in occupied basements. According to the American Lung Association, fibreglass insulation should never be left exposed in a populated space.

Recycled glass bottles, sand, and other elements are used to make glasswool insulation. Fibreglass insulation is sometimes known as glasswool. Fiberglass batts and glass fibre insulation are other names for it. These are melted and spun into fibres at extremely high temperatures. Millions of tiny air-pockets are generated inside the insulation as a result, giving glasswool insulation its excellent insulating characteristics.

Glass wool is an insulating material created from glass fibres bound together with a binder to give it a wool-like feel. Many small pockets of air are trapped between the glass throughout the process, resulting in excellent thermal insulation. Glass wool comes in rolls or slabs, each with its own set of thermal and mechanical qualities. It can also be made as a spray-on or in-place material that can be applied to the surface to be insulated.

Acoustic boards help lessen undesirable reflected sound in any room...

Acoustic boards help lessen undesirable reflected sound in any room...

Open spaces have been known as the trending layout for...

WhatsApp us