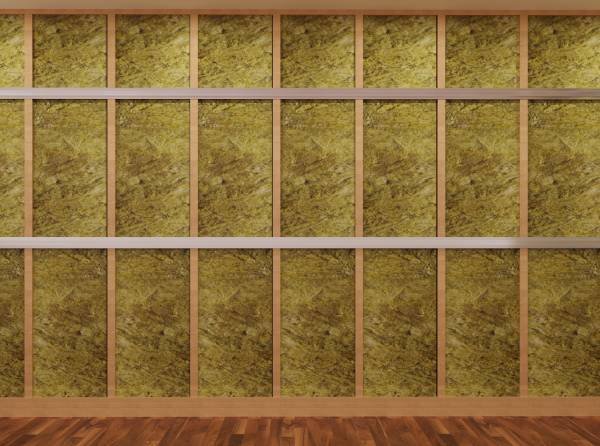

Rock wool is a very rigid fibrous thermal insulating material that is used in building construction, industrial plants, residential properties, multiplexes, auditoriums, and more to prevent fire and control heat loss.

In this article, we will further discuss- how is rock wool prepared? What are its varied applications and benefits? And how is it different from glass wool?

So, let’s get started!

This is made by melting the stones in a furnace at a temperature of 1500 degrees celsius. After this process, the molten rock is converted into dry fibers which are then added to the adhesives and compressed to make rock wool.

his is used for high-temperature insulations like boilers, marine insulation, and industrial insulations which operate at very high degrees of heat.

This is very effective in insulating and controlling a good amount of heat loss and energy costs.

Fire-Resistance: Rock wool holds high-density and is non-combustible in nature therefore it is ideal for preventing fire.”

Moisture-Resistance: Rockwool is highly resistant to moisture, it prevents all sorts of mould and bacterial formations, and it’s also immune to rotting. Thus, it contributes to a healthier indoor ambiance.

Made from stone: A rock wool is made from volcanic rocks, and recycled steel slag. Thus, it exudes better insulation benefits and is more durable as compared to fiberglass or glass wool.

Noise-resistance: Nothing can compete with the sound absorption capacity of a rockwool. Unlike other insulations, rock wool is a high-density and innovative insulation that prevents sound and noise to travel from one conductor to another conductor.

It’s good at trapping all the sound waves and vibrations and therefore it is widely used in auditoriums and big movie theaters.

These are the reasons why pro contractors and many homeowners don’t settle for anything less than Rockwool!

HVAC: It is used for duct wraps and piping.

Buildings: It is used in buildings for roofs, ceilings, interior and exterior walls, floors, and piping.

Metallic buildings: It is used in metallic buildings for roofs, walls, and piping.

Industrial application: It is used for power plants, furnaces, turbines, storage tanks, steam piping, and much more in industrial organizations.

It’s good at trapping all the sound waves and vibrations and therefore it is widely used in auditoriums and big movie theaters.

These are the reasons why pro contractors and many homeowners don’t settle for anything less than Rockwool!

With a lightweight, PVC laminated suspended gypsum ceiling not as sturdy as a slab. Therefore, you must ensure to know the amount of weight it can support. So, avoid hanging any chandeliers, ceiling lights or decorative pieces to it before that. For precautions, it is suggested to install a piece of plywood just above the gypsum sheet to give it strength to hold the weight of the piece.

Furthermore, make sure to get the ceiling fan rod installed on the ceiling slab prior to the false ceiling construction. Whether it’s gypsum false ceiling, wooden ceiling, pvc tile ceiling, or any other lightweight ceilings, install the fan rod first. Moreover, when it’s the matter of heavy items like swings, always remember to install a sturdy hook in the slab before making the false ceiling allowing it to hold the weight of the swing.

Appearance: As rock wool is made from volcanic rocks, it is mostly brown or grey in color. It has a hard and rough surface and comes in the form of big slabs.

Density: It is rigid, hard, and made at high densities.

Heat-resistance: It provides the best heat resistance at 700 to 750 degrees of heat temperatures therefore it is best to be used for industrial applications where work is done at high heat temperatures.

Applications: It has high industrial applications. It is used in boilers, turbines, furnaces -where steam is used abundantly and high heat resistance is needed to save any heat loss.

Ease of use: It is available in the form of pipes and slabs and it is widely used in varied industrial applications.

For the past 37 years, we have been helping highly reputed architects, interior designers, decorators, and builders with the right and high-quality products like false ceilings, partitions, insulations, etc to fulfill their diverse needs. We are here to help them with the right products that are available at the right rates.

Glass wool is very different from rock wool, although both tend to have the same benefits and uses, but their formation and features set them apart from each other.

Appearance: A glass wool is yellow in color, it’s soft and available in the form of slabs or rolls.

Density: A glass wool starts from low density as it is very soft, and thus, it can be made in different forms and shapes. It has many uses – it can be rolled or used in-between the wall partitions.

Heat-resistance: It gives the best performance at 230 to 260 degrees celsius of heat temperatures, and therefore it’s not used in industrial areas or high heat temperature areas.

Applications: It is used in cinema halls, conference rooms, building interiors, sheds, multiplexes, recording studios, and for ducting purposes. It has many applications as it is available in different densities and forms.

Ease of use: Glass wool is widely used in offices and homes as it is available in different forms like slabs, and rolls and now, it is also available in the form of acoustic tiles.

Both rock and glass wool are known to save energy costs and reduce echo. These are widely used for better sound absorption, and saving extra energy consumption costs.

They are known to create a better and peaceful environment by effective sound insulation. Additionally, they both are best at fire and moisture-resistance. Thus, these are an indispensable need for many builders and constructors.

We are available in your service 24*7, contact us and our experts will help you with the right technical details to help you choose the best insulation for your property.

Call us today at 9625332290 Or email us at dm@unidusindia.com

WhatsApp us