Acoustic boards help lessen undesirable reflected sound in any room...

Thermal acoustic insulation is utilised in commercial, industrial and military applications for heat and sound reduction. This multi-function isolation with machine enclosures, pipelines and valves is utilised in fabrication and processing systems. On and off the road, the flooring, doors, side panels and mobile equipment and military engine bays convey composite constructions that contain thermal and acoustic material.

There are many different insulating materials available, but to make the proper decision you do not need a Ph.D. in materials science.

The thermal insulation functions as an obstacle to heat transmission. We create warmth within the home in winter and efficient isolation maintains the heat there. When the home has a predetermined temperature and the heater is turned off automatically, our thermostat recognises. However, the heater has to produce heat to maintain the specified temperature without insulation. This leads to an increase in energy consumption. The roles are changed in the summer. Then the heat is outside, and much of it does not penetrate the house via the same insulation. This decreases the demand for continuous operation of air-conditioning systems and minimises the cost of electricity.

Thermoacoustics is the interplay between changes in acoustic waves’ temperature, density and pressure. Thermoacoustic heat motors may be easily powered by solar or waste heat and regulated proportionally. They can utilise low-temperature heat, making it excellent for heat recovery and low power applications. In comparison to traditional engines, the components contained in thermoacoustic engines are often relatively basic. It’s easy to manage and maintain the gadget. When partially molten glass tubes are linked to the glass containers, thermoacoustic phenomena can be detected. A loud and monotonous sound is sometimes spontaneously generated.

Thermal insulation means a decrease in heat transmission between thermal or radioactive contact items. Acoustic isolation is any way to reduce the sound intensity of a certain source and receiver.

The main features of thermal insulation, condensing and inorganic insulation materials characteristics as well as biological high void insulation materials and the glass and glass are dealt with at thermal and acoustic isolation. The book also provides descriptions of noise insulation, computerised insulation calculations, isolation materials’ fire characteristics. The book discusses the theory of water vapour dispersion, and dehumidification, thermal insulation, heat transfer (via conduct, convection, radiation). Both forms of common usage isolation materials inhibit the transmission of radiant heat by reflecting or impairing heat flow.

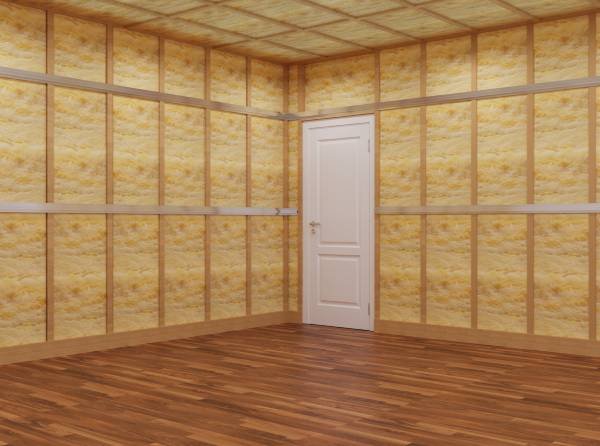

The greatest approach to counteract undesirable noise and enhance your quietness and serenity is by adding some kind of acoustic insulation. However, with just the smallest amount of investigation, a variety of Acoustic Insulation kinds may be found to absorb, degrade and dispel noise; they all assist regulate the sound to a far more controllable degree. However, it helps to know the characteristics of the different acoustic isolations to select the most appropriate kind for your project.

Sound insulation solutions may be used to suppress noise in people’s homes, work places or studio buildings using acoustic insulation materials. Acoustic mineral wool is one of these items and it is intended in wooden and metal partition walls, timber joists and other sealed rooms where noises might rebound to absorb airborne sound. The usage of acoustic insulators can efficiently absorb sound and, if utilised with other sound insulation solutions, can assist to comply with Part E Building Regulations (and when used as a component in a building).

Acoustic boards help lessen undesirable reflected sound in any room...

Acoustic boards help lessen undesirable reflected sound in any room...

Acoustic boards help lessen undesirable reflected sound in any room...

WhatsApp us